Smart watches have become one of the must-haves in modern life. They can not only provide basic functions such as time, step counting, heart rate, etc., but also connect to mobile phones and support various applications. One of the core components of smart watches is the PCB circuit board. This article will introduce the measurement methods and precautions of smart watch PCB to help readers better understand and use smart watches.

1. Measurement method of smart watch PCB

1. PCB appearance size meaSmart watches have become one of the must-haves in modern life. They can not only provide basic functions such as time, step counting, heart rate, etc., but also connect to mobile phones and support various applications. One of the core components of smart watches is the PCB circuit board. This article will introduce the measurement methods and precautions of smart watch PCB to help readers better understand and use smart watches.

1. Measurement method of smart watch PCB

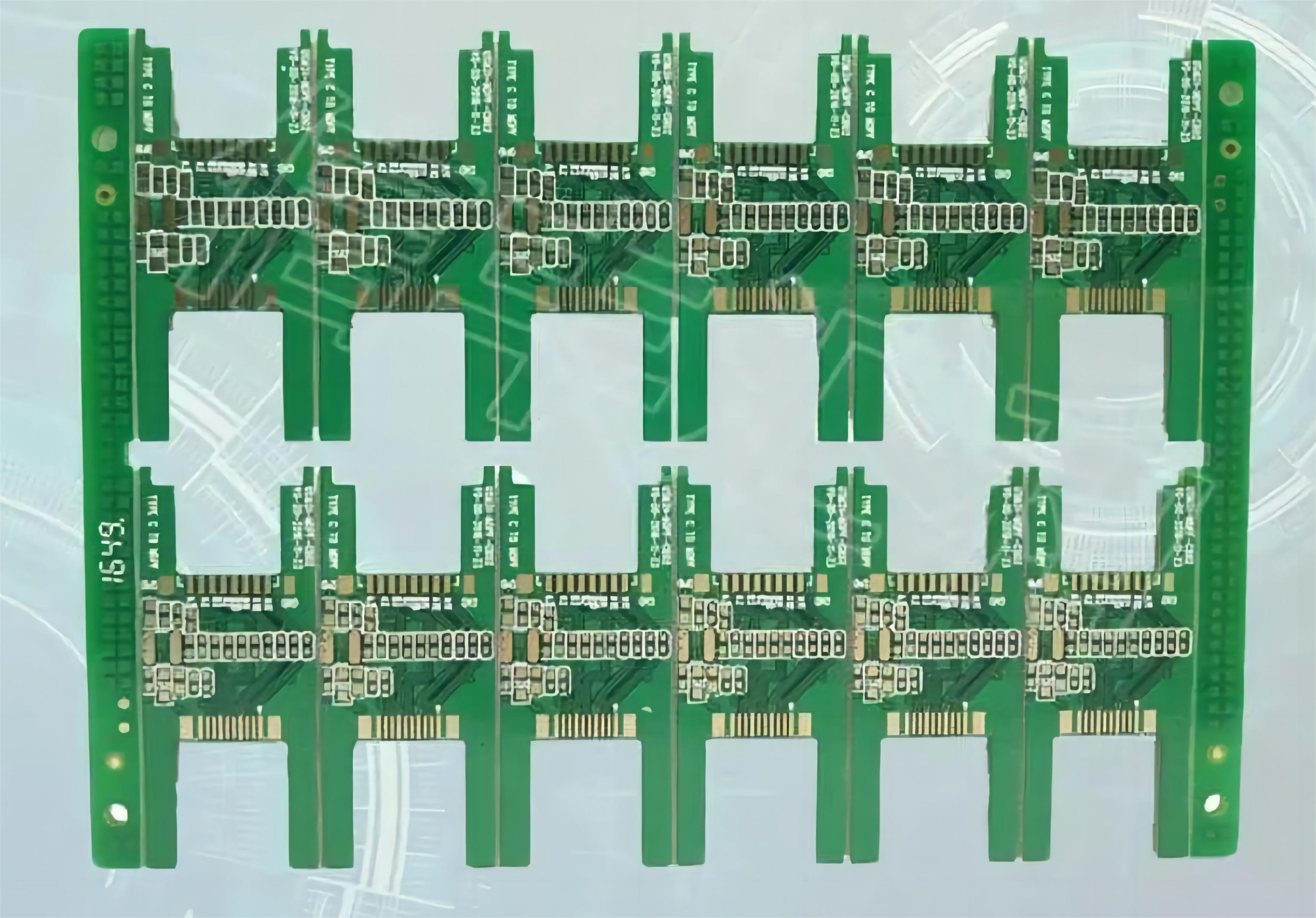

1. PCB appearance size measurement

The appearance size of the smart watch PCB is one of the important measurement indicators. You can use a professional digital ruler or microscope to measure and accurately record the length, width and thickness of the PCB. During the measurement process, pay attention to avoid the influence of external forces on the PCB to avoid inaccurate measurement results.

2.PCB line tracing measurement

Line tracing is one of the main methods for evaluating PCB quality. Line tracing measurement can be performed using a multimeter or a professional circuit tester. Touch the tester's probes to the lines on the PCB one by one, and observe the instrument readings to confirm information such as the line's connectivity and resistance value. Line tracing measurement can also help find potential short circuits, open circuits, and other problems.

3. PCB electrical characteristics measurement

The electrical characteristics of smart watch PCB are an important indicator of its performance. Electrical characteristics can be measured using instruments such as oscilloscopes and spectrum analyzers. By observing waveforms, spectrum and other data, the electrical performance of the PCB in working condition, such as signal stability and anti-interference ability, can be evaluated.

2. Notes on Smart Watch PCB

1. Anti-static

When measuring PCB, be sure to prevent the generation and accumulation of static electricity. Static electricity may damage components on PCB and affect the normal operation of the circuit. Use anti-static measures such as anti-static gloves and workbenches to ensure that there is no static electricity in the environment and on the body during measurement.

2. Handle with care

When operating PCB, be sure to handle with care to avoid the influence of external forces on PCB. The components and circuits on PCB are very delicate, and excessive force may cause damage or disconnection. Use special tools and pay attention to the operating force to ensure the safety of PCB.

3. Environmental control

When measuring PCB, the environment should be dry, dust-free and odor-free. Humidity, dust and chemicals may have a negative impact on PCB. Choose a dry and ventilated workplace to ensure a dust-free and humidity-free environment to provide good conditions for measurement.

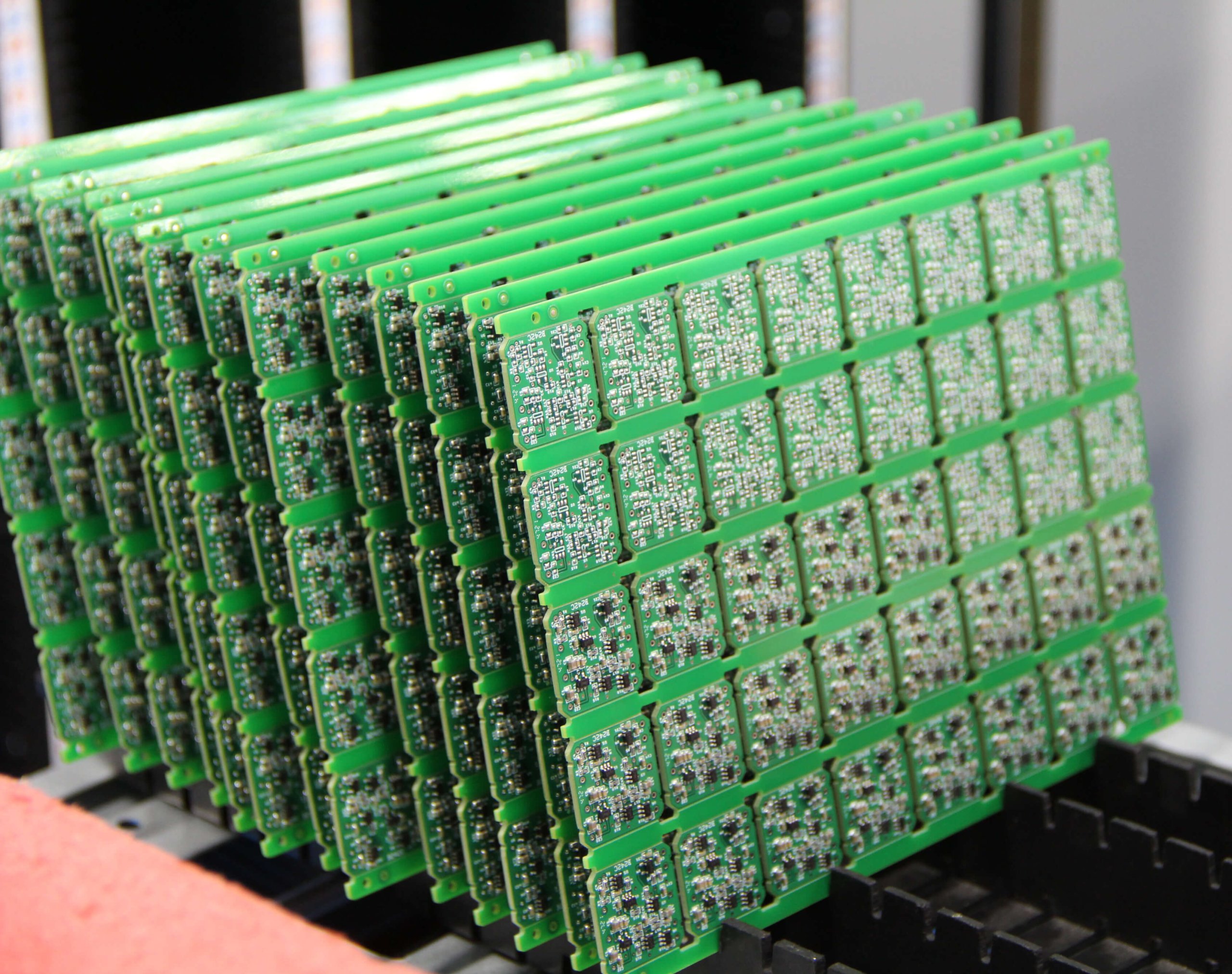

Asinda has 17 years of experience in PCB manufacturing, specializing in the production of various high-layer precision circuit boards, blind and buried via boards, high-frequency boards, hybrid laminates, metal substrates, rigid-flex boards, etc. If you need, you can contact us at any time.

https://www.linkedin.com/pulse/methods-precautions-measuring-smart-watch-pcbs-rsjbc