What does the one stop PCBA services include?

This article will introduce in detail the service content of PCBA processing.

PCB one stop services includes:

1. Design support schematic design: Transform the electronic circuit principle into a manufacturable circuit diagram. PCB layout: According to the circuit schematic, reasonable layout of electronic components to ensure the optimal path of signal transmission and power distribution.

2. Material selection Substrate material: Select FR-4, CEM series and other substrate materials to meet different performance requirements. Copper foil thickness: Select the appropriate copper foil thickness according to the current carrying capacity.

3. Manufacturing process Lithography: The use of lithography technology to form circuit patterns on the substrate.

Etching: Removing the copper layer that is not protected by the photoresist to form circuit wiring.

Drilling: Provides access for component installation and circuit connection.

4. Assembly service

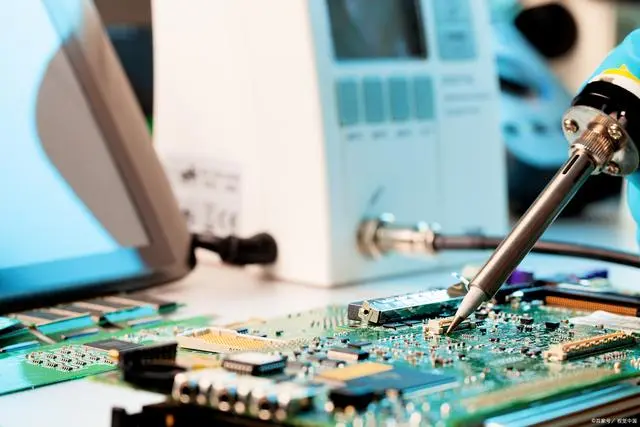

SMT (Surface Mount Technology) : Precise placement of surface mount components.

DIP: For larger components, through hole technology is used for installation.

5. Quality Inspection AOI (Automatic Optical Inspection) : Detect welding defects, missing components or misplacement.

X-ray inspection: Detect hidden defects inside the PCB.

Functional test: Make sure the PCB works properly according to the design requirements.

6. Post-processing

Cleaning: removal of contaminants remaining during processing.

Coating: Provide a protective layer such as three anti-paint to improve the durability and moisture resistance of the PCB.

next time ,we will write about the precautions of PCBA.