Do you know the advantages of PCBA rails ?

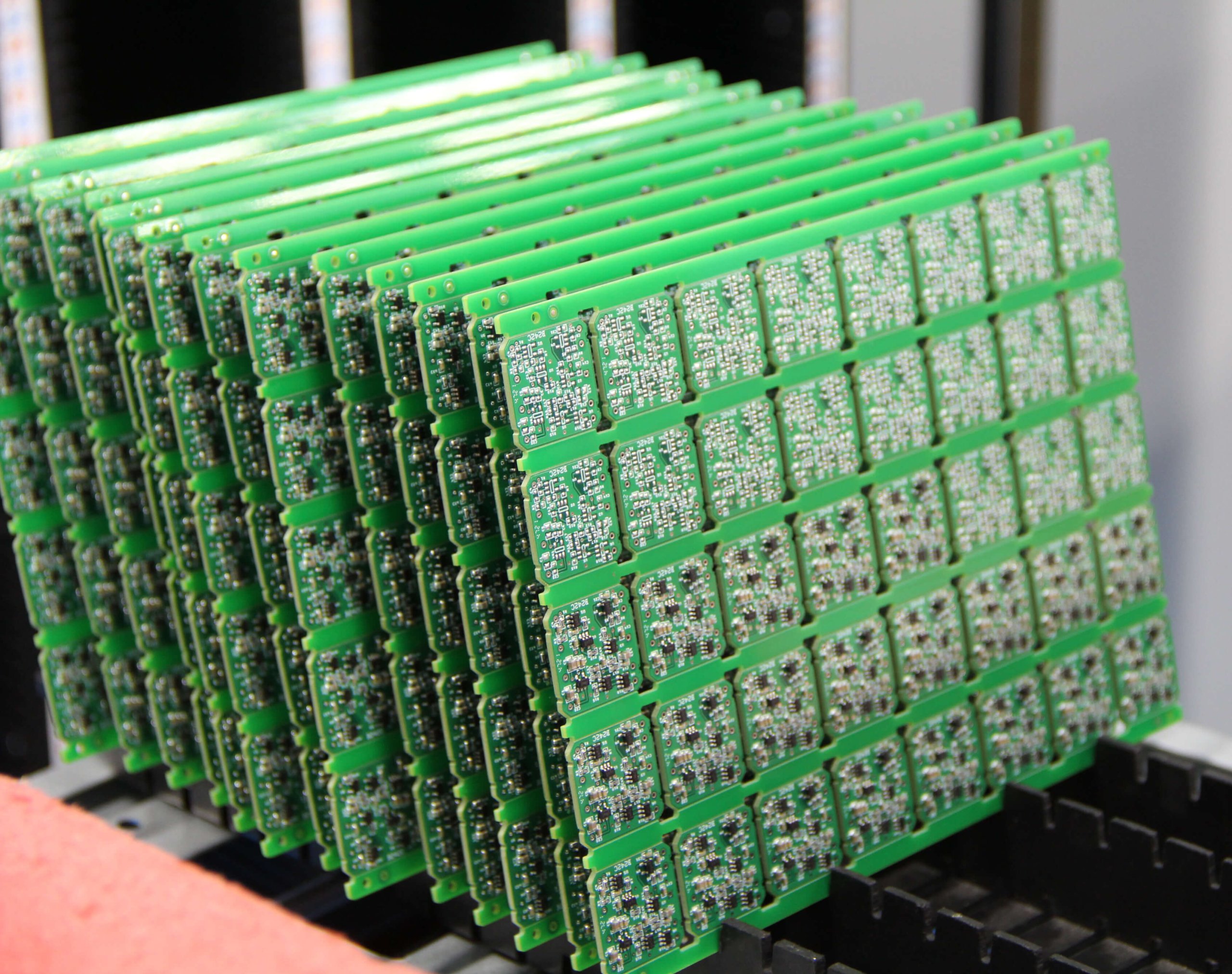

In this era of ubiquitous electronic products, PCBA (Printed Circuit Board Assembly, that is, printed circuit board assembly) as the basic component of electronic equipment, its importance is self-evident. In the manufacturing process of PCBA, a seemingly insignificant but crucial detail is often overlooked - that is, the PCBA rails. Today, we will explore in depth, do you really understand the rails on the PCBA board? What are the benefits?

First of all, let's clarify what is the rails of the PCBA board.

In simple terms, the rails in the production process, in order to facilitate subsequent assembly, testing and transportation and other links and specially designed and retained one or more borders. These borders usually do not contain any electrical connections and are not involved in the actual functional implementation of the product, but they play an integral role in the entire lifecycle of the PCBA.

Second, the benefits of the rails, do you really know?

1. Easy to fix and position

In automated production lines, PCBA need to be fixed and transmitted by various mechanical fixtures. The presence of a rail provides a precise grasping point for these fixtures, ensuring the stability and accuracy of the PCBA during processing. This not only improves production efficiency, but also greatly reduces the rate of defective products caused by positioning errors.

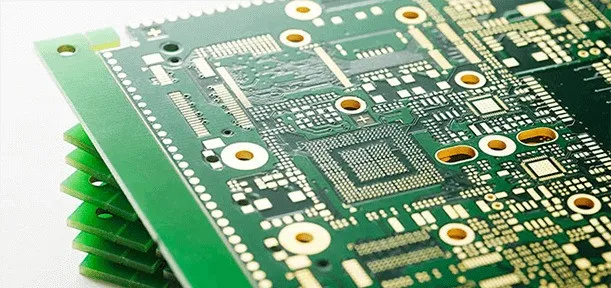

2. Protect circuit components

During the assembly, testing and packaging of PCBA, the components on the circuit board are easily impacted or scratched by external forces. The rails acts as a barrier to protect these sensitive components from damage to a certain extent, ensuring the reliability and durability of the product.

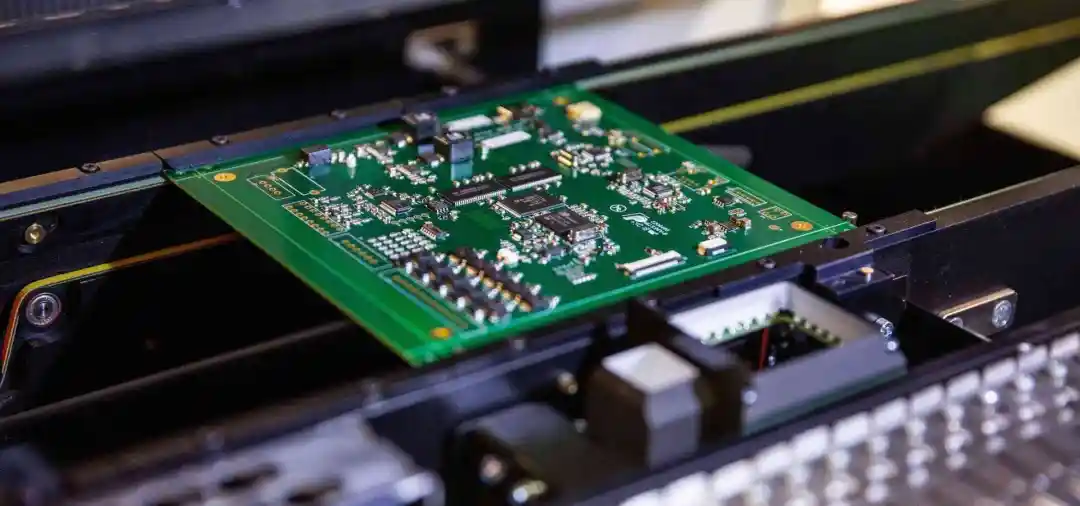

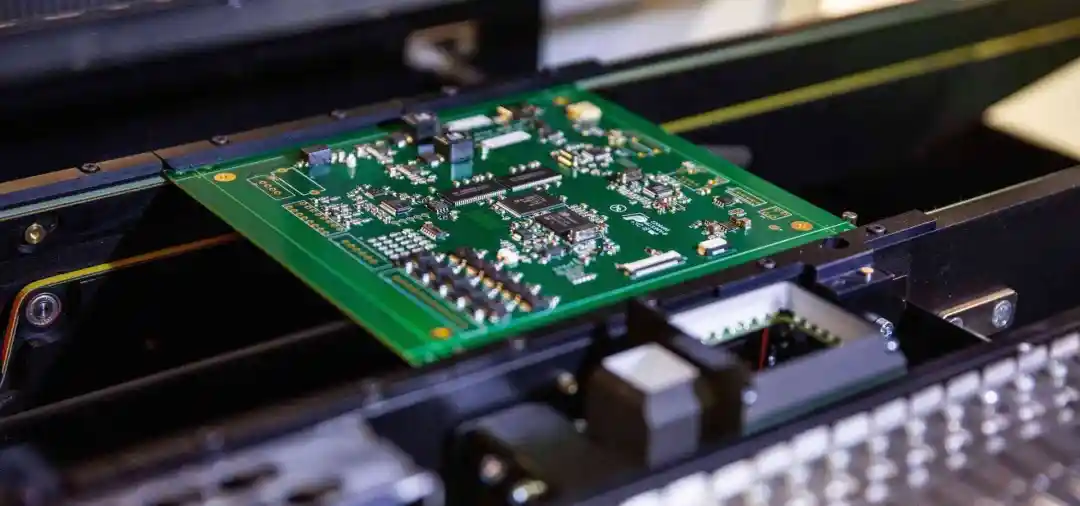

3. Assist in testing and inspection

In the later stage of production of PCBA, a series of functional tests and quality control checks are required. The rails can be used as the contact point of the test probe to simplify the test process and improve the test efficiency. It also provides quality inspectors with a more intuitive inspection path to identify and fix potential problems.

4. Optimize material management

On the production line, different batches of PCBA often need to be effectively differentiated and managed. The rails can be used as an identification area to record batch information, production date and other key data through labeling, inkjet, etc., which helps to realize material traceability and inventory management.

5. Adapt to automated production

With the advancement of intelligent manufacturing, automated production equipment is becoming more and more popular. The rail is often designed with compatibility with these devices in mind, allowing PCBA to move smoothly in and out of various automation equipment for efficient and accurate processing and assembly.