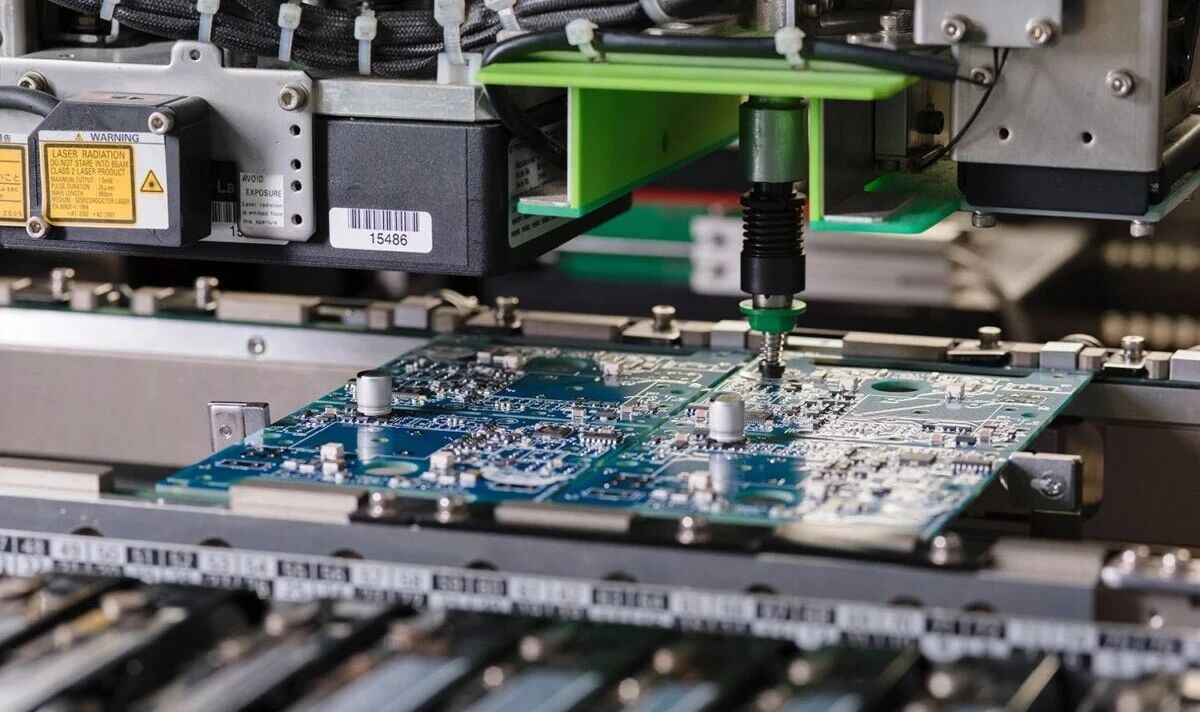

PCBA Program burnin g is a core technology of circuit board assembly, which is directly related to the function realization and performance optimization of products.

first,Definition of PCBA Program burning.

PCBA burning, in short, is the process of writing pre-written program code to the memory on the PCBA . PCBA , as a core component of electronic products, forms a complete electronic system through the assembly of printed circuit boards and various components. Program burning, on the other hand, is the "injection" of software-level instructions and logic into the hardware system, so that it can operate in a predetermined manner.

Second, the way of program burning.

Program burning is mainly divided into two ways: offline burning and online burning.

1. Offline burning: This method is usually suitable for program verification and small batch production before mass production. It needs to be connected through adapters and different packages of chips to achieve program burning. Although the operation is relatively complex, it is very effective in small batches or specific scenarios.

2. Online burning: it is more convenient and efficient. It uses the standard communication bus of the chip (such as USB, SWD, JTAG, UART, etc.) to burn the program directly. Because the interface communication rate is moderate and the cost is relatively low, this method has been widely used in mass production.

Third, the role of program burning

Program burning plays a crucial role in the manufacture of electronic products, and its role is mainly reflected in the following aspects:

1. Function realization: The microcontroller, ARM controller and other chips in electronic products need to be written in advance to control its operation. Through the burning program, these chips can perform various operations according to the requirements of the design, so as to realize the basic function of the product.

2. Performance optimization: In addition to realizing basic functions, program burning can also improve the operating efficiency and response speed of the equipment by optimizing the program code. This is essential to enhance the user experience and the market competitiveness of the product.

3. Parameter configuration: In electronic products, many parameters (such as the IP address and port data of the WiFi module) need to be set by burning. The accurate configuration of these parameters is the key to ensure the normal operation of the product. Security: Program burning can also write various security mechanisms, such as encryption algorithms, authentication, etc., to ensure the security of device data and prevent malicious attacks or tampering. This is of great significance for protecting user privacy and ensuring device security.

4. Remote management and upgrades: Some high-end devices support remote firmware upgrades (Over-The-Air, over-the-air). This relies on the underlying program burned by the device at the factory, so that the device manufacturer can push new programs or repair patches remotely without recycling the device, greatly improving the ease of equipment maintenance.