In the PCBA process, functional testing (FCT) is the core link to ensure the reliable performance of products. As a one-stop PCBA manufacturer with 18years of industry experience,Asindaprovides customers with high-quality PCBA with zero defects through a strict FCT inspection process.

First, FCT Inspection: The Core of FCTinspection is a key process in the PCBA production process, used to verify whether the functions of the PCBAsmeet the design requirements. Asinda's FCT inspection covers the following core contents:

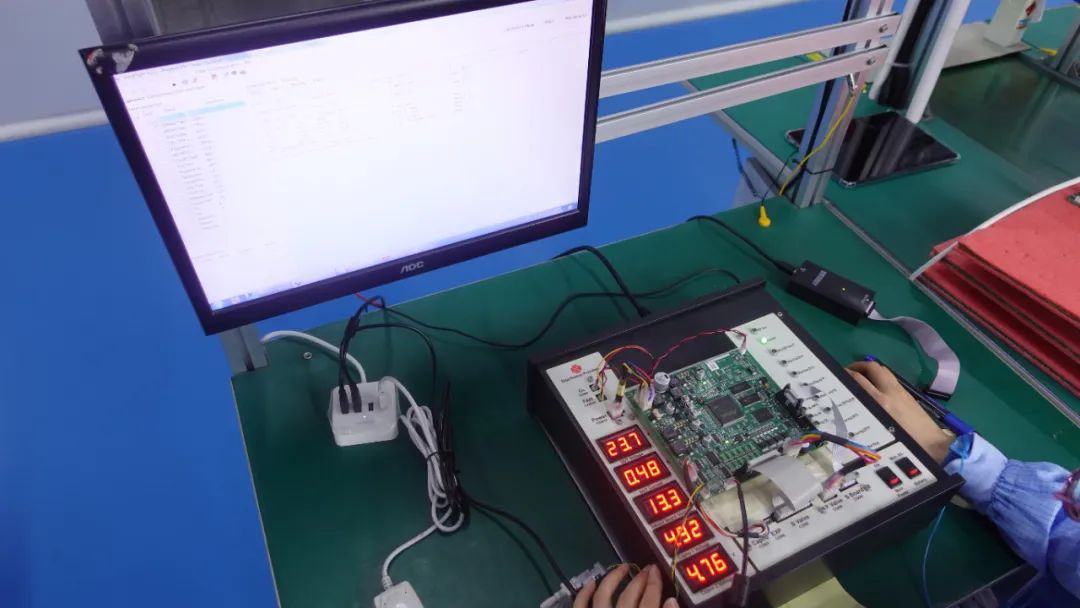

1. Power supply testing: Check the power supply stability of the PCBAsto ensure that the voltage and current are within the normal range.

2. Signal transmission test: Verify the integrity and accuracy of signal transmission to prevent communication failures.

3. Functional module testing: Conduct individual tests on functional modules such as the MCU, sensors, and communication interfaces to ensure their normal operation.

4. Load testing: Simulate the real working environment to test the stability of the circuit board under high load.

Second,Three Major Advantages of Asinda FCT Testing

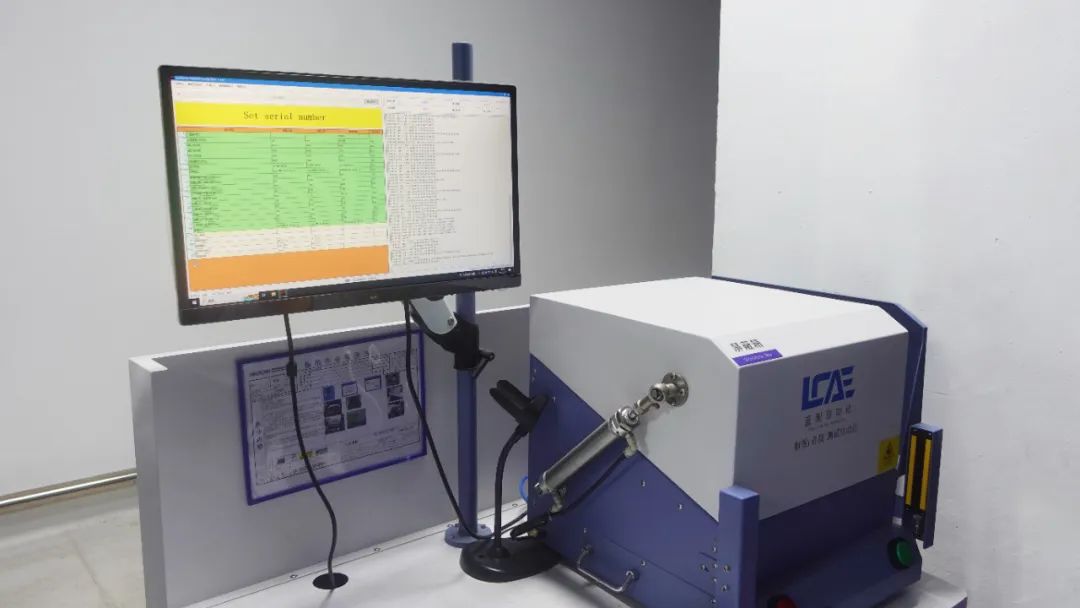

1. Fully automated testing: Utilizing intelligent FCT testing equipment to enhance detection efficiency and accuracy.

2. 100% coverage: Every PCBA board undergoes rigorous functional testing to ensure zero-defect delivery.

3. Rapid feedback: By integrating with the MES system, test data can be monitored in real time, problems can be quickly identified, and production can be optimized.

Third,How FCT Inspection Helps Customers Succeed

1.Reduce After-sales Failures: Through strict FCT inspection, the failure rate of products after leaving the factory is reduced, and customer satisfaction is enhanced.

2.Shorten the delivery cycle: An efficient testing process accelerates the time to market for products, helping customers seize market opportunities first.

3.Reduce comprehensive costs: Minimize rework and returns, and optimize production costs.

Forth,Four Core Advantages: Asinda's Quality Commitment As a one-stop PCBA service provider, Asinda offers comprehensive support to customers with four core advantages:

●R&D support: Provide comprehensive technical support from PCB design to embedded software to facilitate product innovation.

● Fast service: 7× 24-hour online consultation, with the fastest quotation available within 24 hours, and the MES system ensures efficient delivery.

● Zero defects: 19 strict quality inspection procedures, FCT inspection ensures that every PCBA board meets the highest standards.

● One-stop service: From design and development to finished product assembly, we provide a full-process electronic assembly solution.