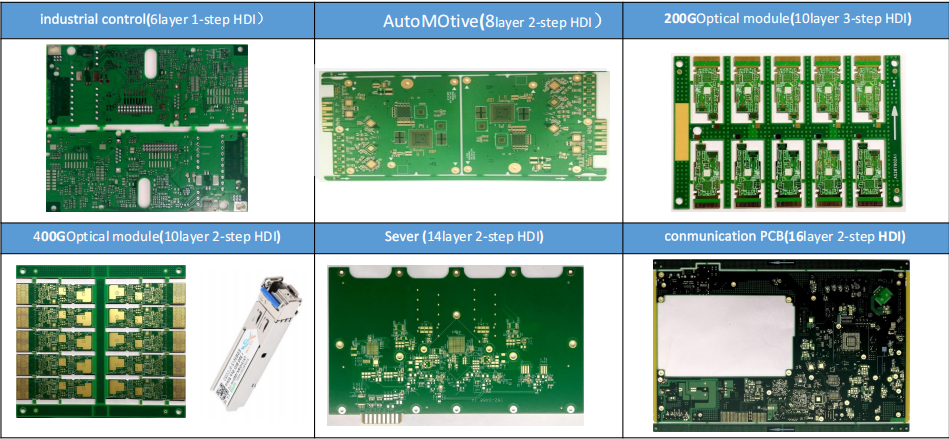

The 1-step HDI board is relatively simple and easy to control.

The 2-step HDI process starts to be troublesome.

One reason is the alignment issue, and the other is the drilling and copper plating.

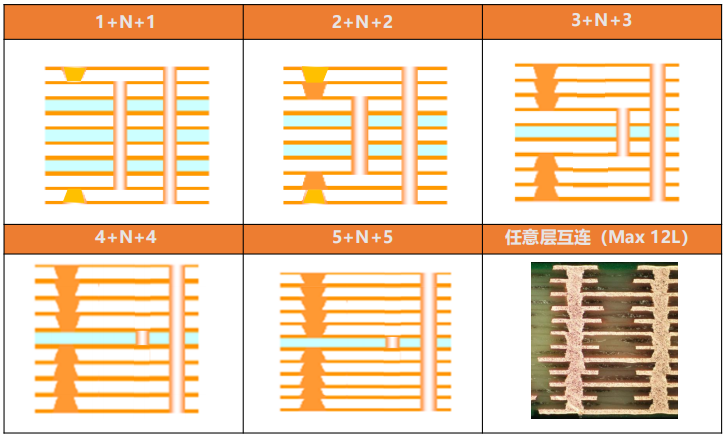

There are many types of 2-step designs.

Firstly, the positions of each step are staggered and need to be connected to the next adjacent layer. The wires are connected to the middle layer, which is equivalent to two 1-step HDI.

Secondly, the two 1-step holes overlap, and the 2-step HDI holes are achieved through superposition. When processing two 1-steo holes, there are many process points that require special control.

The third method is to drill directly from the outer layer to the third layer (or n-2 layer). This process is quite different from the previous one, and drilling is more difficult.

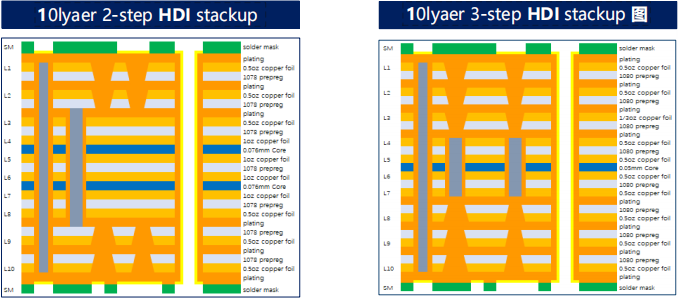

The 1and 2 step of the six-layer board require laser drilling. The six-layer 1-step HDI board refers to blind holes: 1 to 2 layers, 2 to 5 layers, and 5 to 6 layers. Among them, 1 to 2 layers and 5 to 6 layers require laser drilling machines.

The six-layer 2-step HDI board refers to blind holes: 1 to 2 layers, 2 to 3 layers, 3 to 4 layers, 4 to 5 layers, and 5 to 6 layers, which means that two laser holes need to be drilled.

First, drill 3 to 4 layers of buried holes, then press 2 to 5 layers, then drill 2 to 3 layers and 4 to 5 layers of laser holes, press 1 to 6 layers again, and then drill 1 to 2 layers and 5 to 6 layers of laser holes. The last step is to drill through the hole. It can be seen that the 2-step HDI board has been pressed twice and laser drilled twice.

In addition, 2-step HDI boards can be further classified into staggered 2-step HDI boards and stacked 2-step HDI boards.

A 2-step HDI board with staggered holes refers to the interlaced arrangement of blind holes in layers 1 to 2 and 2 to 3, while a 2-step HDI board with stacked holes refers to the overlapping arrangement of blind holes in layers 1 to 2 and 2 to 3, for example: blind holes: 1 to 3 layers, 3 to 4 layers, 4 to 6 layers.