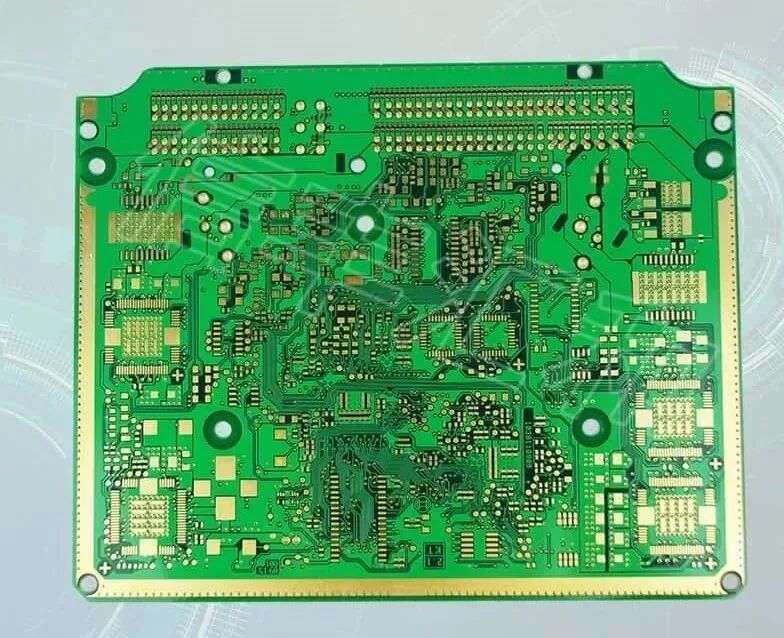

The manufacturing of automotive PCBs is uniquely defined by stringent safety-centric standards, extreme environmental adaptability, and full-lifecycle traceability—all to ensure reliable operation throughout a vehicle’s 10-year/200,000-kilometer service life.

1. Component & Material Specifications: Automotive-Grade Exclusivity

• All components must comply with AEC-Q series certifications (e.g., AEC-Q100 for semiconductors, AEC-Q200 for passive components), ensuring ultra-low temperature drift (<1%/℃) and high anti-vibration performance. Commercial-grade components used in ordinary PCBs are strictly prohibited.

• Base materials (e.g., PCB substrates) must have high thermal resistance (Tg value >170℃) to withstand engine compartment temperatures up to 150℃, far exceeding the Tg <130℃ requirement for consumer PCBs.

2. Manufacturing Process: Precision & Durability-Focused

• Solder paste printing requires ultra-high precision (steel mesh aperture tolerance ±0.01mm) and lead-free high-temperature soldering (peak temperature 245±5℃) to avoid cold joints under vehicle vibration.

• Mandatory conformal coating (e.g., acrylic, silicone) is applied via dipping or spraying, forming a 20-50μm protective film to resist oil, moisture, dust, and chemical corrosion—an absent step in standard PCB manufacturing.

3. Environmental & Reliability Testing: Simulating Extreme Vehicle Conditions

• Thermal shock testing: PCBs undergo 1,000+ cycles of -40℃ to 125℃ temperature swings (10℃/min rate) to verify resistance to thermal fatigue.

• Vibration & mechanical testing: Exposed to 10-20G sinusoidal vibration (5-2000Hz) for 100+ hours, simulating road颠簸 (bumpy road conditions).

• Electromagnetic Compatibility (EMC) testing: Must meet ISO 11452 standards to avoid interference with on-board systems (e.g., engine control, radar), a test rarely required for non-automotive PCBs.

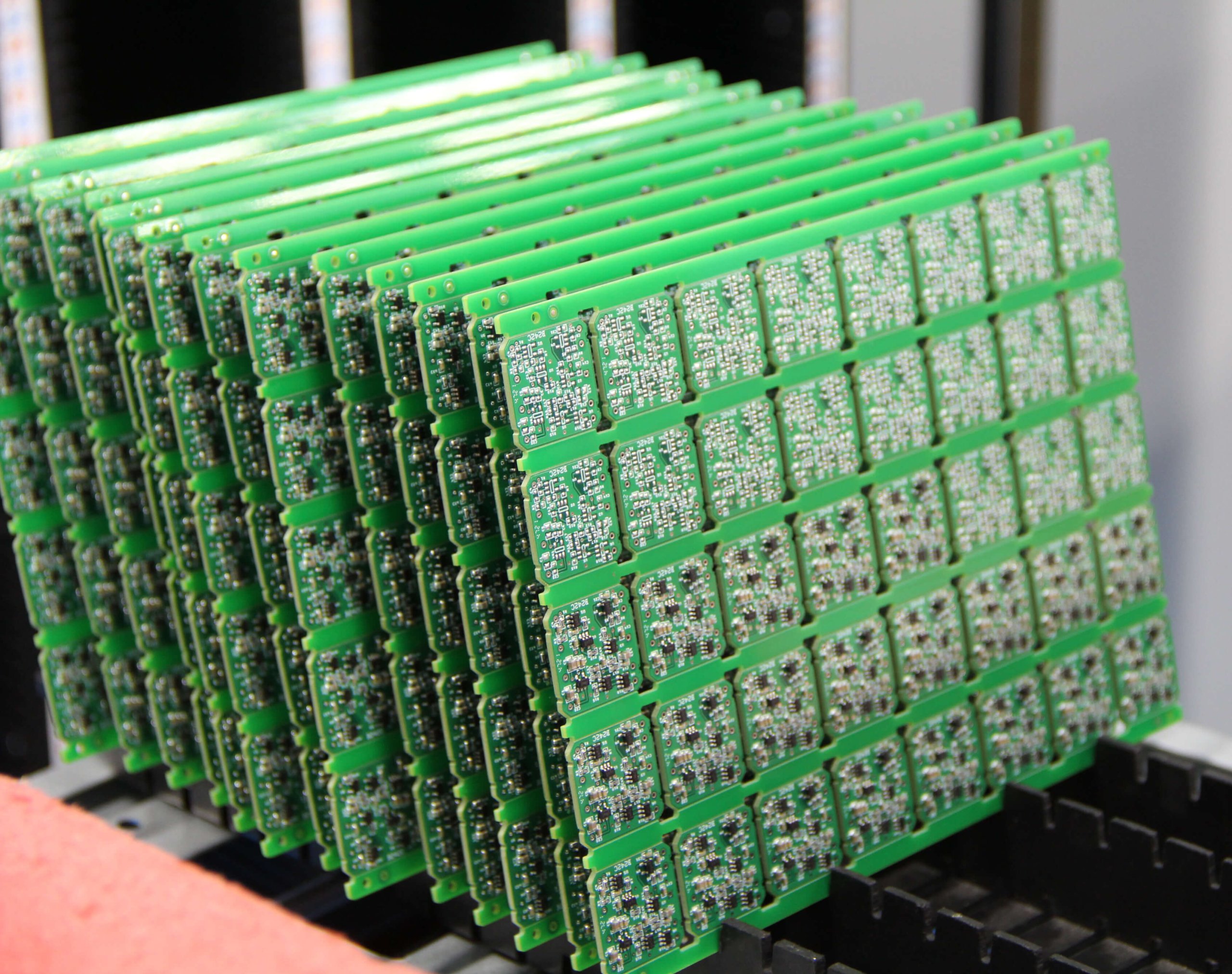

4. Quality Traceability: Full-Lifecycle Accountability

• Each PCB is assigned a unique QR code/barcode, tracking component batch numbers, production operators, soldering parameters, and test results—enabling reverse tracing from the finished vehicle back to individual components.

• Strict compliance with IATF 16949 quality management system mandates documented records for every manufacturing step, with no exceptions for random sampling (100% inspection is required).