Compared to the oxygen 8-zone reflow oven, the nitrogen 10-zone reflow oven has core advantages in three key dimensions: better soldering quality, stronger process compatibility, and more controllable long-term costs. The specific differences are as follows:

1. Soldering Quality: Upgrade from "Qualified" to "High-Quality"

• Reduce Oxidation and Improve Solder Joint Reliability: Nitrogen is an inert gas that can isolate air (oxygen), preventing oxidation of solder (such as lead-free solder) and component pins during soldering. The formed solder joints are brighter and fuller, reducing the risk of cold solder joints and bridging by more than 50%. It is especially suitable for precision components (such as 0201 packages, BGA/CSP).

• More Precise Temperature Zones and Temperature Control: The 10-zone oven has 2 additional heating sections compared to the 8-zone oven, which can more delicately divide the "preheating - soaking - reflow - cooling" curve. It can adapt to different heat-sensitive components (such as sensors and chips) and avoid component damage caused by rapid temperature rise.

2. Process Compatibility: Cover More High-Demand Scenarios

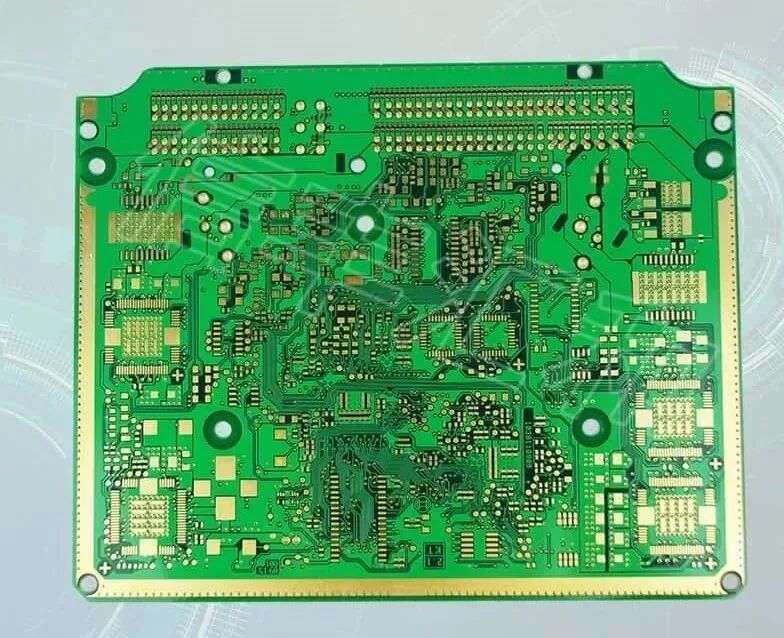

• Support Lead-Free/Special Solder: Lead-free solder (such as SAC305) is prone to oxidation in an oxygen environment, which can be solved by a nitrogen atmosphere. At the same time, it is compatible with various types of solder such as high-temperature solder and low-temperature solder, meeting the soldering needs of complex PCBs (such as multi-layer boards and mixed-package boards).

• Adapt to High-Precision PCB Production: For high-density PCBs with line width and spacing less than 0.1mm and extremely small solder joint spacing, the nitrogen environment can reduce solder splashing, avoid bridging, and increase the yield by 30%-40%.

3. Long-Term Costs: "Initial Investment" for "Long-Term Savings"

• Reduce Rework Costs: The improvement in soldering yield directly reduces the number of rework and repair times, saving labor and material costs (especially for high-value components, the rework cost is extremely high).

• Reduce Equipment Wear and Tear: The nitrogen environment can reduce the oxidation loss of heating tubes and conveyor belts in the furnace, extending the service life of the equipment by 2-3 years and lowering equipment maintenance and replacement costs.