SPI solder paste inspection vs AOI optical inspection: The two core quality control methods that PCBAs engineers must know

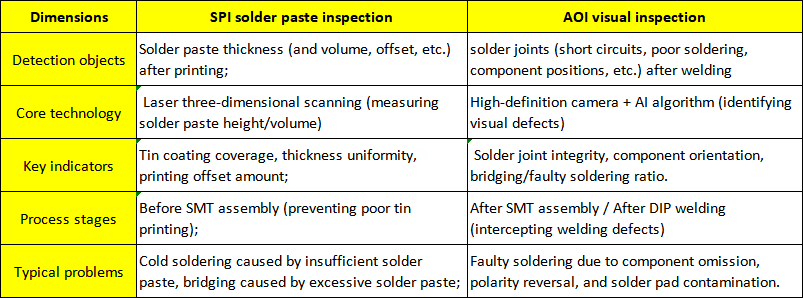

I. Core Difference: Distinctive Process Stages and Inspection Objectives

SPI (Solder Paste Inspection) and AOI (Automatic Optical Inspection) are indispensable quality control steps in PCBA production. However, there are fundamental differences in the inspection objects, technical principles, and application stages between the two:

II. Asinda Quality Inspection System: Dual Detection for Coordinated Defect Interception Through the dual guarantees of SPI pre-interception and AOI post-verification, Asinda achieves full-process quality control:

SPI pre-interception: Real-time monitoring of solder paste printing accuracy. If an excessive offset is detected (±0.02mm), the steel mesh parameters will be adjusted immediately to prevent batch defects in welding.

• AOI post-control: Combined with 3D SPI data, high-precision imaging analysis is conducted on the solder joints. The defect recognition rate of the solder joints reaches 99.9%, ensuring a delivery yield of ≥99.9%.

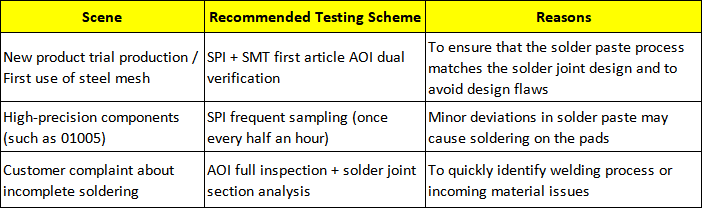

III. Engineer's Pitfall Avoidance Guide: Precise Selection of Testing Timing

Asinda's four core advantages guarantee the quality control of PCBA. As a one-stop service provider with 19 years of experience in the PCBA field, Asinda achieves full-process quality control through the following capabilities:

• Assisting R&D: From PCB design to software debugging, full-cycle technical support to avoid "design-production" disconnection.

• Zero defects: 19 quality inspection processes + X-RAY/3D SPI/AOI coverage, with a soldering yield rate of ≥ 99.9%.

• Rapid service: MES system tracks and monitors test data in real time, responding to abnormalities within 2 hours.

• One-stop service: Own SMT/DIP workshop + global inventory of over 50,000 components, reducing delivery cycle by more than 50%.