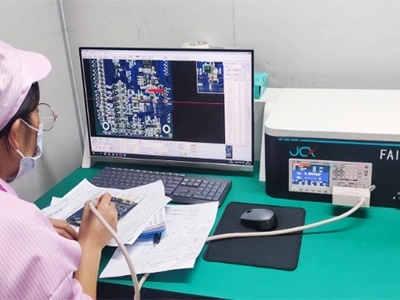

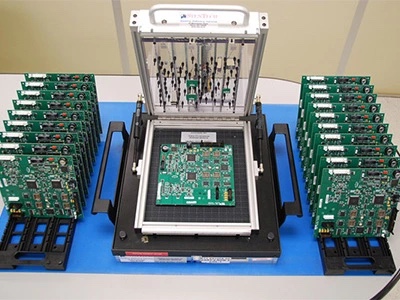

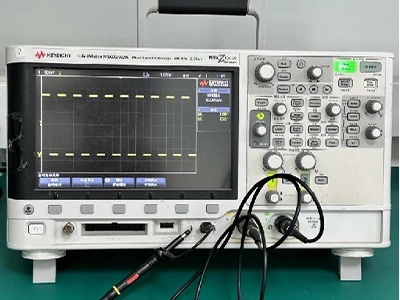

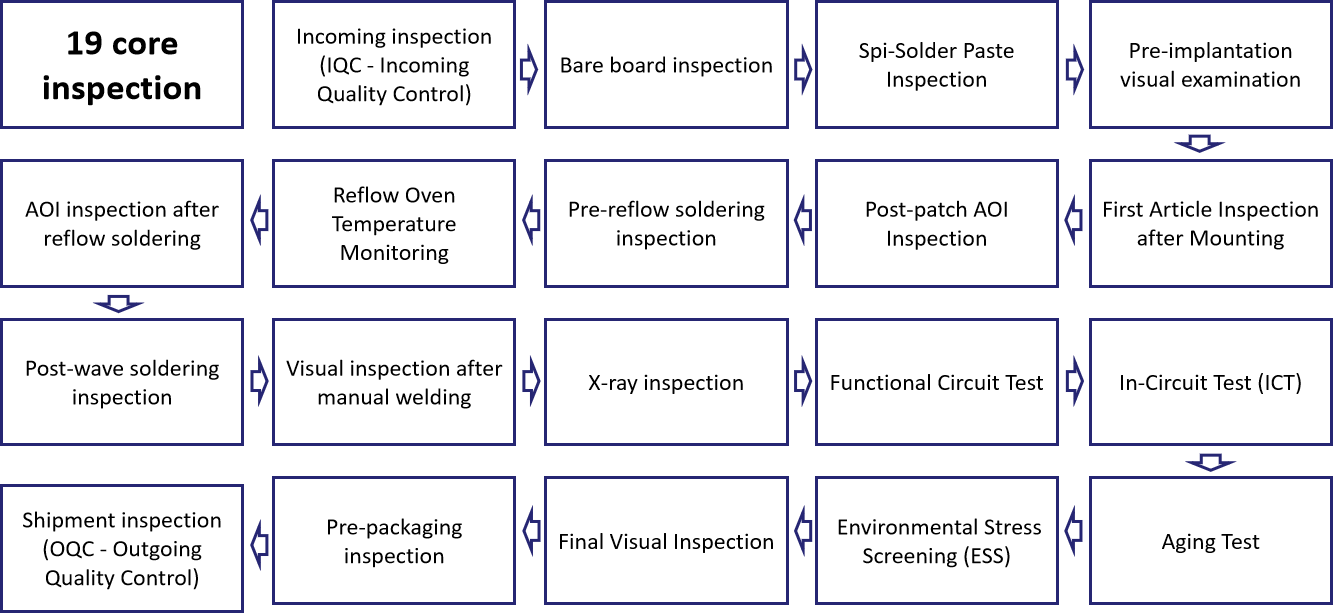

All boards are strictly inspected, in addition to manual visual inspection, we use automatic testing,testing equipment, such as A0l optical inspection, FAl first article inspecton system, X-ay inspection,ICT testing, plug-in online visual inspection instrument, thermal infrared detector high and low temperature tester ,PCBA function test, online and offline program burning, oscilloscope, FCT function test, program burning and other equipment.