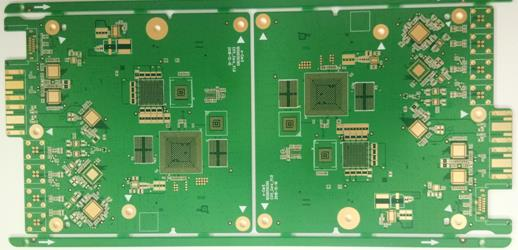

Have you ever met such below issues on HDI manufacturing ? How to can we deal with it?

1. Line breakage and short circuit: Due to the high integration and precision design of the hdi board, the line spacing is small, and the slightest mistake during the processing may lead to line breakage or short circuit.

2. Poor welding: The welding point is not strong, virtual welding, cold welding and other problems, will seriously affect the electrical performance and reliability of the hdi board.

3. Material problems: The quality of substrate materials, copper foil, solder resistance ink and other materials is unstable, which will lead to the overall performance of the hdi board.

4. Improper process control: Improper control of key processes such as etching, drilling and electroplating will also lead to quality problems.

here Effective response to how to avoid.

1. Optimize design and process

In the design stage, fully consider the characteristics of the hdi board, reasonable layout of the line, to avoid too compact design.

At the same time, key processes such as etching, drilling and electroplating are optimized to ensure processing accuracy and stability.

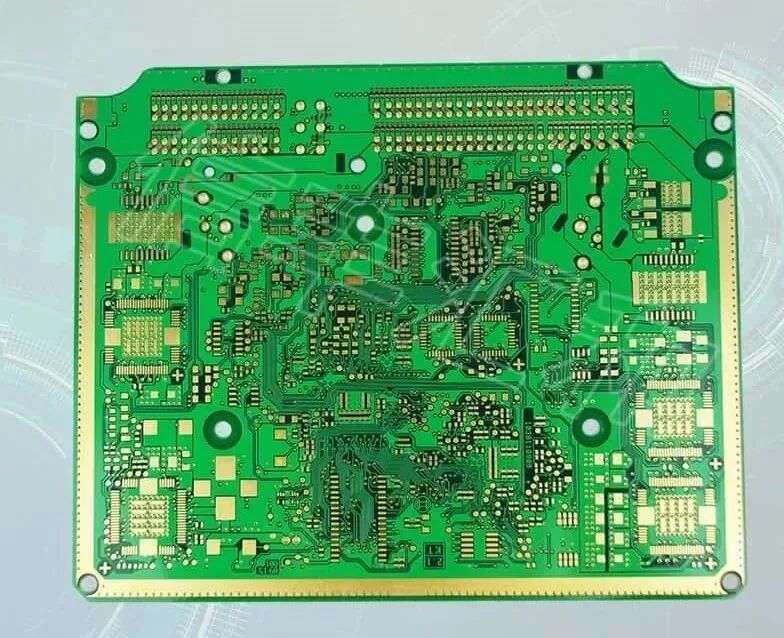

2. Strict material selection and control

Choose reputable, quality guaranteed suppliers to ensure the quality of raw materials.

Strict inspection of incoming raw materials to ensure compliance with standards.

3. Strengthen process control and quality inspection

Establish a sound process control system to monitor and record key processes in real time.

Introduce advanced testing equipment to carry out comprehensive and detailed quality testing of hdi board.

4. Improve staff skills and awareness

Strengthen staff skills training, improve staff's awareness of hdi board quality problems and response ability.

Improve the quality awareness of employees, so that every employee understands the importance of quality.

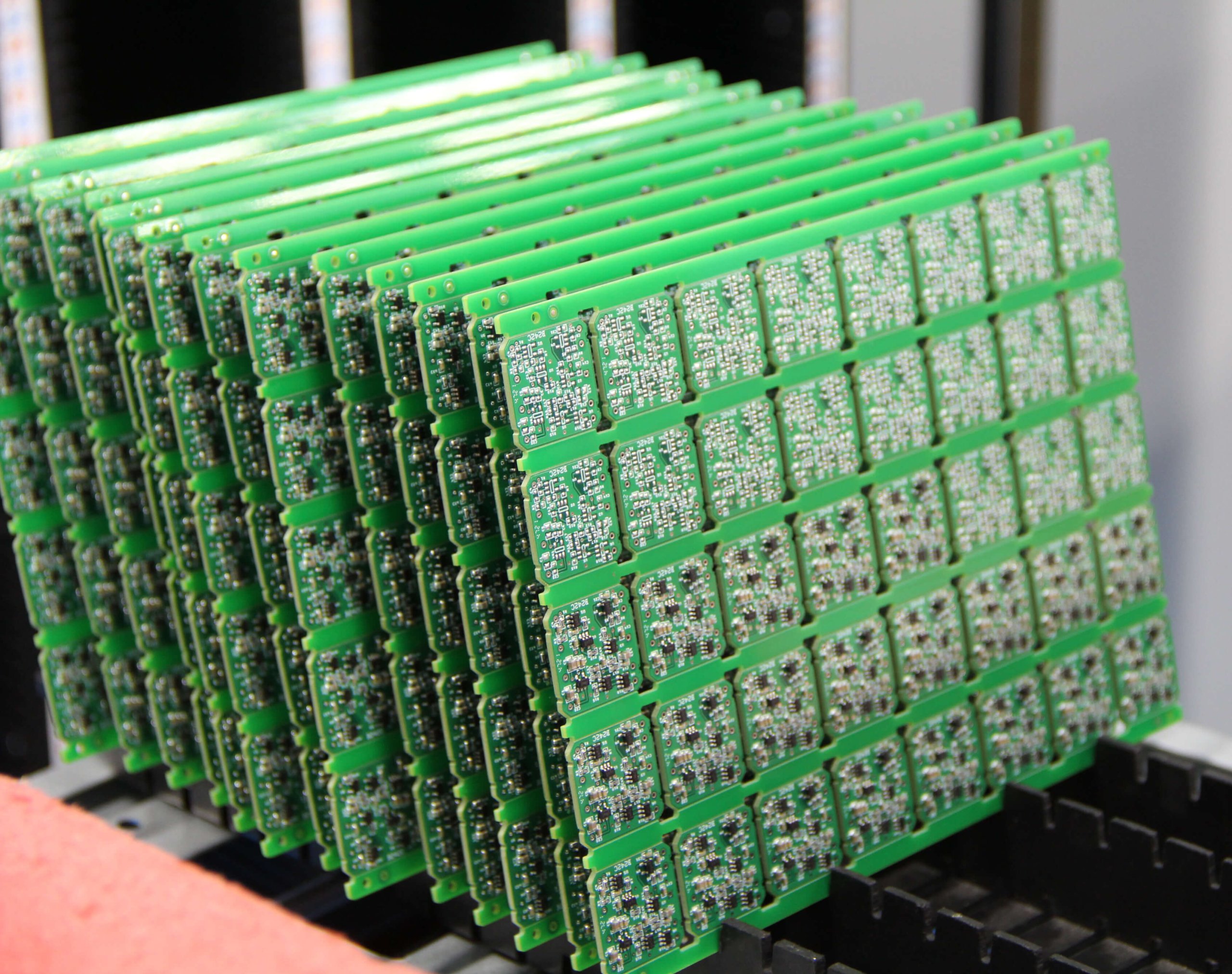

5. Establish a quality management system

Establish a complete quality management system, from design, raw materials, production to testing, each link has clear standards and processes.

Identify problems and make continuous improvement through regular quality reviews and internal audits.

Only in this way can we ensure that the quality of HDI boards is stable and reliable to meet market demand.