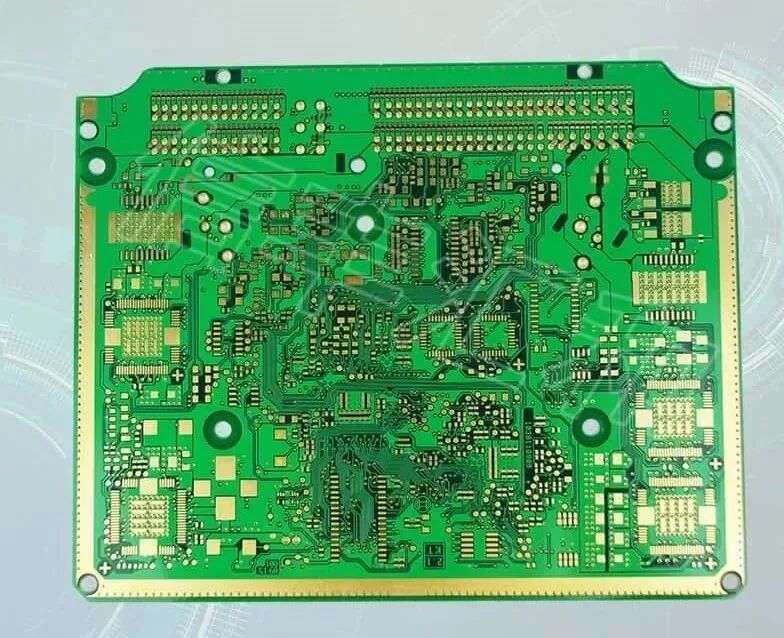

With the rapid rise of the new energy vehicle market, the importance of the battery management system (BMS), as the "heart" of new energy vehicles, is self-evident. In this system, high-performance printed circuit boards (PCBs) play a vital role.

1. PCB in BMS: a bridge between connection and control

In new energy vehicles, BMS is responsible for monitoring and managing the operating status of the battery pack to ensure the safety and reliability of the battery. As an important part of BMS, PCB is responsible for connecting key components such as battery cells, sensors, and controllers, and also carries the functions of collecting, transmitting, and processing battery data. Therefore, high-performance PCB is the basis for BMS to achieve efficient, safe, and reliable operation.

2. Key technologies of PCB in BMS

High-precision data acquisition technology:

BMS needs to collect accurate voltage, current, temperature and other data for each cell in the battery pack. Therefore, the PCB needs to have high-precision data acquisition technology to ensure that the collected data is accurate. This includes the use of high-resolution analog-to-digital converters, optimized signal conditioning circuits, and accurate reference voltages.

High-speed data transmission technology:

BMS needs to communicate with vehicle controllers, charging equipment, etc. in real time to transmit battery pack status information and control instructions. Therefore, PCBs need to have high-speed data transmission technology to ensure the real-time and reliability of data. This includes measures such as adopting high-speed bus technology, optimizing PCB layout and wiring, and reducing noise interference.

Efficient heat dissipation technology:

New energy vehicles will generate a lot of heat during operation, especially during charging and discharging. Therefore, the PCB in the BMS needs to have efficient heat dissipation technology to ensure that the temperature of the circuit board is always within a controllable range. This includes using materials with high thermal conductivity, optimizing the heat dissipation structure, and adding heat dissipation fans.

Electromagnetic compatibility (EMC) design:

There are many electronic devices in new energy vehicles, and the electromagnetic interference between them cannot be ignored. Therefore, the PCB in the BMS needs to have EMC design to ensure that the circuit board can work normally in various electromagnetic environments. This includes the use of shielding, filtering, grounding and other technical means to reduce electromagnetic interference.

3. The impact of PCB technology on BMS performance

High-performance PCB technology can significantly improve the performance of BMS. High-precision data acquisition technology can ensure that BMS accurately determines the status of the battery pack and improves battery efficiency and safety. Secondly, high-speed data transmission technology can ensure real-time communication between BMS and vehicle controllers, charging equipment, etc., improving the response speed and reliability of the system. Efficient heat dissipation technology can ensure that the BMS can operate normally even in high-temperature environments, improving the stability and reliability of the system. Electromagnetic compatibility (EMC) design can reduce the impact of electromagnetic interference on BMS performance and improve the system's anti-interference capability.

By using key technical means such as high-precision data acquisition technology, high-speed data transmission technology, efficient heat dissipation technology, and electromagnetic compatibility (EMC) design, the performance and reliability of BMS can be significantly improved. In the future, as the new energy vehicle market continues to develop and expand, high-performance PCB technology will play a more important role in BMS.