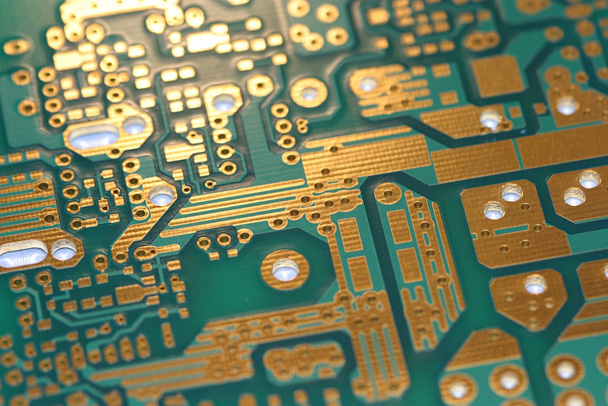

1. HASL

advantages: low cost, suitable for SMT process, suitable for lead-free welding, mature process.

Cons: Not suitable for wire binding, limited to particularly thick or thin plates, not suitable for contact switch designs.

2.ImSn

advantages: Excellent flatness, suitable for fine pitch /BGA/ smaller components, with medium cost lead-free surface treatment technology. Cons: sensitive to processing, short shelf life, erosion to solder resistance layer.

3.ENIG

advantages: flat surface, lead-free, suitable for PTH (plated through hole), long shelf life.

Cons: Expensive, non-reworkable, may cause loss in signal RF circuits.

4. OSP

advantages: simple process, flat surface, suitable for lead-free welding and SMT, low cost, environmentally friendly.

Cons: Limited reflow times, not suitable for crimping technology, wire binding, high storage requirements.

5. ImAg

advantages: high weldability, good surface smoothness, low cost and lead-free (in line with RoHS standards).

Cons: High storage requirements, easy to be contaminated, short assembly window after removal from the package.

6. ENEPIG

Advantages: Provide good electrical performance and protection, more environmentally friendly than ENIG.

Cons: Information is not explicitly provided in search results.

7. Electrolytic Hard gold

advantages: wear-resistant, smooth and hard surface, containing cobalt and other elements, the surface looks brighter.

Cons: Information is not explicitly provided in search results.

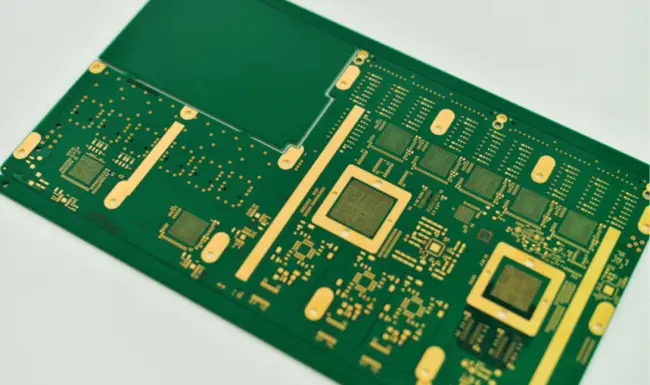

Choosing the right PCB surface finish technology can significantly improve the performance and reliability of boards and electronic products.