Improper use of three Conformal Coating will cause damage to components on PCB, Which areas on the board should be shielded and which areas can be coated?

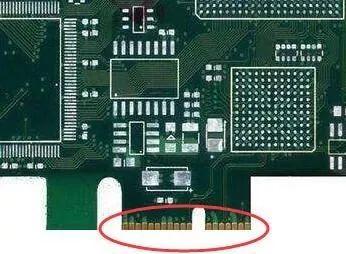

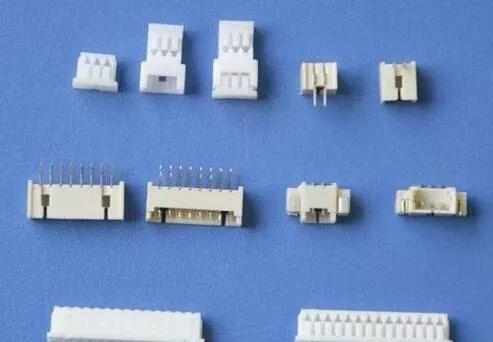

Generally, connectors, switches, radiators, goldfingers, positioning holes and other positions should be shielded before coating.

these Areas that cannot be coated with Conformal Coating:

1. Areas requiring electrical connection, such as gold pads, gold fingers, metal through holes, test holes, etc.;

2. Battery and battery fixing rack;

3. Connector;

4. Fuse and shell;

5. Heat dissipation device;

6. Jumper;

7. Lens of optical device;

8. Potentiometer;

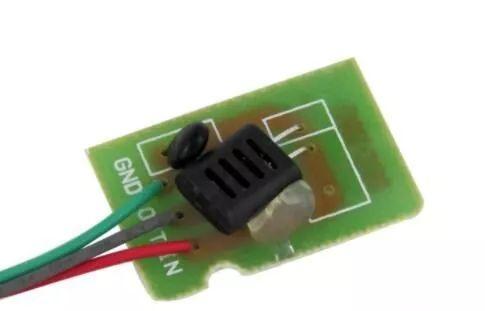

9. Sensors;

10. No sealed switch;

11. Other areas where coating can affect performance or operation. For example, inductive components, coated with three anti-paint is likely to affect the electrical properties, must be tested in advance

Areas that must be coated:

Except the above mentioned areas, all other solder joints, component legs, and component conductors should be coated, generally the whole board after protection treatment of the components that must be shielded.

#PCBManufacturing #PCBAssembly #PCBfactory