What industry standards and key elements should PCB for automotive quality inspection meet ?

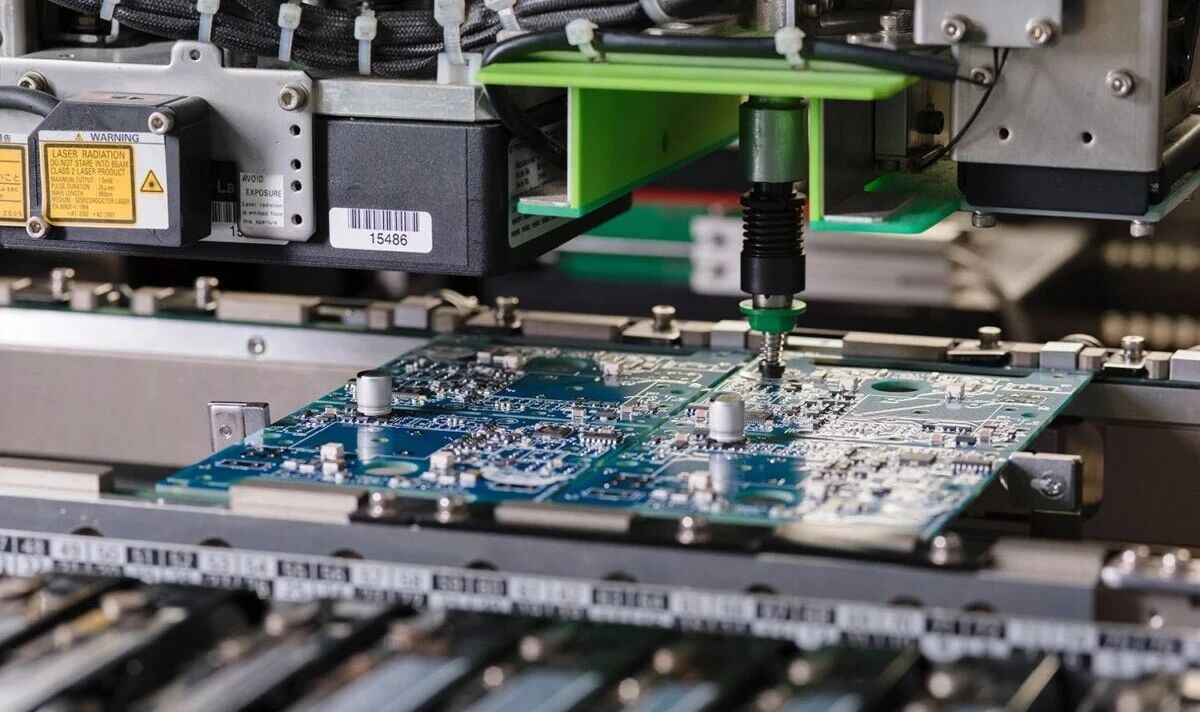

As the core component of electronic systems, automotive PCBs not only need to carry and connect various electronic components, but also maintain stable operation under extreme temperature, vibration and humidity conditions.

Therefore, it is crucial to ensure the quality and reliability of automotive PCBs. What are the standards for manufacturing automotive PCBs? International Organization for Standardization (ISO) standards:

International Organization for Standardization (ISO) standards:

ISO 9001: Quality Management system standard, which ensures that enterprises systematically manage their quality control processes.

ISO/TS 16949 (now superseded by IATF 16949): Specific quality management system requirements for the automotive industry, specifically for continuous improvement and defect prevention in the supply chain.

· International Electrotechnical Commission (IEC) standards:

IEC 60068 series: Environmental test standards, including temperature cycling, vibration, shock and other tests to ensure PCB performance in harsh environments.

IEC 61508:Functional safety standard, which sets requirements for the development and operation of safety-related electronic systems.

Society of Automotive Engineers (SAE) standards:

SAE J-STD-001: Welding standard for electronic assembly to ensure welding quality and reliability.

SAE AS5553: Standard to Prevent the use of counterfeit and substandard electronic parts.

· Other professional standards:

IPC standards:such as IPC-A-600 (Rigid Printed board Acceptance standard), IPC-A-610 (Acceptability standard for electronic components), provide detailed quality acceptance criteria for PCB manufacturing and assembly.

Key test element

Material and design verification: Select environmentally friendly materials that comply with RoHS (Directive restricting the use of certain hazardous substances), and verify the electrical performance and mechanical structure rationality of PCB design through software simulation and preliminary prototyp

Electrical Performance Test:Including on-resistance test, insulation resistance test, high voltage test, etc. to ensure the correct connection of circuits and electrical isolation performance.

Temperature Cycle Test:Simulates extreme temperature changes to evaluate the thermal stability of PCB materials and solder joints.

Humidity Test:Checks the electrical performance and moisture resistance of PCBs in high humidity environments.

Vibration and Shock Test:Simulate the vibration and shock during vehicle traveling to verify the mechanical strength and connection reliability of PCB.

·Functional Safety Verification:For PCBs involving safety-critical systems, additional functional safety assessments are required to ensure that a minimum level of safety can be maintained under fault conditions.

Traceability and documentation:from raw material procurement to the finished product out of each link need to have detailed records to facilitate traceability and quality control.

In conclusion, the quality inspection of automotive PCB circuit boards is a comprehensive process that involves strict control of multiple aspects from design, material selection to production and testing. Following the above industry standards and key inspection elements is the basis for ensuring the safe and reliable operation of automotive electronic systems.